Transparency is the key to managing supply chain risk. But some businesses only focus on selective financial information from their suppliers, which can leave them exposed. Beyond creditworthiness, there are many additional threats to consider—such as second-, third- and fourth-tier suppliers as well as natural disasters, fires, strikes and sanction risks.

Executive Summary

Without sophisticated technology to proactively identify and analyze complicated supply chain risks, full transparency for threat detection is hard to achieve. In this profile of “riskmethods,” L.S. Howard describes how the company uses artificial intelligence and machine learning to provide real-time data for supply chain risk management, helping customers identify the weakest points of their supply networks.However, without sophisticated technology to proactively identify and analyze these supply chain risks, full transparency for threat detection is hard to achieve. Manual tracking is next to impossible for complicated global supply chains.

When Munich-based riskmethods was launched in 2013, its CEO Heiko Schwarz wanted to use technology to build a platform that helps companies with their supply chain risk management (SCRM).

Schwarz saw a gap in the marketplace and the ability to harness real-time media monitoring and real-time monitoring of risks to back risk management practices, explained Constantine Limberakis, senior director of Product & Solutions Marketing for riskmethods, in an interview with Carrier Management.

At the time, businesses would manage risk with their suppliers by getting information on a quarterly basis about their certificates of insurance and their financials, he said, noting that real-time monitoring of risk did not exist.

Nine years later, the company has built a platform driven by artificial intelligence (AI) that harnesses big data to monitor global supply chain risks.

After all, to be forewarned is to be forearmed. Another way of putting it is to “manage before damage.”

“The way I would best describe what our platform does is we help identify, mitigate, avoid and actively monitor all the risks that are mapped on our supply chain platform,” Limberakis continued.

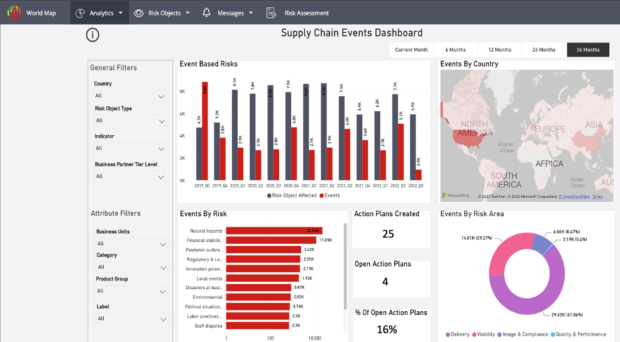

The company’s AI technology analyzes 500 million sources of data on a daily basis across 300,000 different media and partner data sources focused on cyber, financial, sanctions and sustainability data. These provide the basis of risk scorecards for all the different types of threats a company wants to track, he explained.

More than a dozen global languages are included in the analysis.

The scorecard will have a number of different factors across different areas of risk, which is then organized “in a taxonomy across a number of different risk indicators. To date, we provide almost 200 different risk indicator types,” he said.

Limberakis said these threats include the financial stability of suppliers and countries, their creditworthiness, the capital structure of a supplier, whether a company is efficient, pandemic outbreak information, supplier strikes and labor disputes, local geopolitical situations, reputational risks, natural hazards, information on IT outages, and information on compliance requirements and documentation—for example, in the area of environmental, social and governance (ESG) criteria.

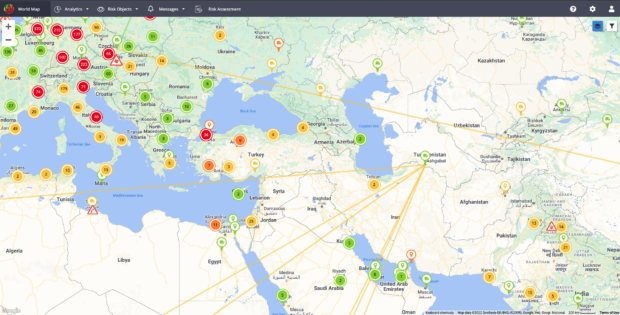

Zurich Insurance, which has had a strategic partnership with riskmethods since March of 2019, said its commercial customers using the riskmethods tools can obtain real-time insights about the health of their entire supply networks via dashboards and an interactive world map, enabling them to identify, assess, mitigate and transfer risks within their supply chain network.

“A lot of our clients describe our tools as ‘a central source of truth’ around supply risk that allows them to standardize how they want to determine when or if they need to take action,” Limberakis said.

“When our supplier was hit by a fire, riskmethods alerted us 30 hours before the supplier did. Because we acted fast to find an alternative source before market prices increased, we realized a purchasing advantage worth $300k,” according to André Hahn, project manager organics, for Stockmeier Group, who was quoted in a brochure detailing Zurich Supply Chain Risk Management Services, the company’s SCRM offering.

Another riskmethods success story can be found in a case study from a customer, Joyson Safety Systems (JSS), an Auburn Hills, Mich.-based company that provides safety systems to automotive manufacturers.

JSS was founded in 2018 through the merger of two global automotive suppliers with operations in the U.S., Japan, Europe and China.

“Going into the merger, JSS did not have supply chain risk management departments in any of its regions. Supplier risk evaluation concentrated primarily on whether the supplier was financially stable…,” said the JSS case study titled “Driving Value Creation with Supply Chain Risk Management – Best Practices from Joyson Safety System.”

“JSS recognized that it needed to consolidate, coordinate, standardize, simplify and digitalize all of its risk management data, processes and systems into one solution,” the study said. As a result, the company decided to find an automated global supply chain risk management solution and ultimately selected riskmethods.

In 2021, JSS began to implement “The riskmethods Solution,” which integrated a base of around 2,000 suppliers within approximately three months. “Using The riskmethods Solution, JSS can map suppliers, its own sites, supply paths and further risk objects such as transport hubs on an interactive world map,” the case study explained.

“Early warnings in near real time enable crisis prevention, quicker adjustment in critical situations and improved risk management capabilities…” The study pointed to the sample of a JSS supplier in Latin America, which burned down.

The riskmethods Solution provided a crucial early warning and helped JSS, which had limited inventory levels, avoid production downtime. “The supplier probably wouldn’t have informed us of the fire until a few days later,” noted Velat Özkilinc, JSS’ executive vice president, chief purchasing officer, who was quoted in the case study.

JSS said the riskmethods tool provides it with:

- Comprehensive transparency and a total view of risk. This includes supplier financial distress, geopolitical situations, natural hazards, reputational risks, and man-made events such as labor disputes and explosions.

- Real-time visibility and warnings on all supply chain risks.

- Risk prevention for better sourcing and awarding decisions, along with proactive supplier development. This allows JSS to avoid conducting business with risky suppliers. “Used in connection with crisis identification, JSS can react as one of the first on the market, enabling it to fulfill the company maxim ‘manage before damage.'”

Sub-Tier Visibility

The riskmethods’ tools not only help customers track their tier 1 suppliers but also can provide sub-tier visibility, said Limberakis.

“Our customers now can see their tier 2 suppliers, so they’re able to get a much wider view of not only what’s going on directly within their immediate supply chain but also the expanded supply chain of their suppliers’ suppliers,” he said. “This allows them to understand who their tier 1 suppliers are buying from and the kinds of risks this could present.”

With this product, called “riskmethods Sub-tier Visibility,” a customer first invites its tier 1 suppliers to join the riskmethods Supply Risk Network and contribute information on their own sites and suppliers.

By encouraging active participation, “everyone gains true visibility into their joint multi-tier supply network that is otherwise unattainable,” said riskmethods on its website.

Customers can monitor suppliers without getting them to actively participate in the network, Limberakis emphasized. But by joining the network, they can get an additional level of detail and information from their tier 1 suppliers, which also allows them to track the sub-tier suppliers, he said.

“Every manufacturing enterprise depends on their direct suppliers (tier 1), who purchase from their suppliers, the sub-tiers. When you can visualize your suppliers’ suppliers (tier 2) or other third parties, you achieve sub-tier visibility,” said riskmethods. “Although organizations are increasingly gaining tier 1 visibility, sub-tier visibility remains elusive.”

Solution for Real Estate Company

In another case study, a provider in commercial real estate and property investments detailed its own unique requirements for proactive SCRM.

Jones Lang LaSalle (JLL) buys, builds, occupies and invests in a variety of assets including industrial, commercial, retail, residential and hotel real estate. JLL’s clients span a wide variety of industries such as banking, energy, retailing, heathcare, law, life sciences, manufacturing and technology.

Although the company had a mature risk management program, it recognized it needed to take a deeper dive into its supply network, using technology to understand in real time “what its partners are doing, what events are occurring along the supply chain and where these are taking place,” said the JLL case study.

“To achieve the output enabled by machine-learning algorithms and artificial intelligence, you’d need a whole army of people,” said David McBride, executive director, Sourcing Strategy & Performance, JLL, who was quoted in the case study.

JLL chose The riskmethods Solution to obtain full visibility of its supplier and third-party base to improve its risk management and compliance while keeping all divisions of JLL up to date on risk. The solution also permits JLL to demonstrate to clients “that it is actively monitoring threats and proactively reducing risk in its complex global supply chains,” according to the JLL case study.

With The riskmethods Solution, JLL can “visualize its entire end-to-end supply network on a world map,” said the case study.

Within one year, JLL was able to successfully roll out the soution, which helped the company expand its monitoring to include 5,000 suppliers across the world in three regions: the Americas, APAC and EMEA.

“By keeping a close watch on the key area of financial risk, as well as geopolitical, man-made, natural disaster, cyber and reputational risk, the real-estate services company can demonstrate a total view of risk,” the study went on to say.

All members of the procurement team can access risk management data via their mobile phones or web browsers, the case study continued.

The Human Touch

Limberakis said that riskmethods doesn’t rely totally on AI to provide its risk scores. Human intervention is also required. “We have a combination of artificial intelligence and risk data experts who take the information and fine-tune it.”

Data experts will pull in that big data for analysis and make sure the machine-learning algorithms are providing relevant information for understanding the supply chain risk, which also improves relevance for clients over time, he noted.

Nearly 26.2M Workers Are Expected to Miss Work on Super Bowl Monday

Nearly 26.2M Workers Are Expected to Miss Work on Super Bowl Monday  Berkshire-owned Utility Urges Oregon Appeals Court to Limit Wildfire Damages

Berkshire-owned Utility Urges Oregon Appeals Court to Limit Wildfire Damages  Modern Underwriting Technology: Decisive Steps to Successful Implementation

Modern Underwriting Technology: Decisive Steps to Successful Implementation  What Analysts Are Saying About the 2026 P/C Insurance Market

What Analysts Are Saying About the 2026 P/C Insurance Market